- July 1, 2025

- by gNxt Systems

Industry 5.0: How RPA Companies in India Are Enabling Smart Factories

The manufacturing landscape is undergoing a revolutionary transformation with the rise of Manufacturing 5.0. Unlike its predecessor, which focused primarily on automation and efficiency (Industry 4.0), Manufacturing 5.0 emphasizes collaboration between humans and intelligent machines. At the heart of this evolution lies Robotic Process Automation (RPA), a technology that is rapidly reshaping the shop floor and back office alike.

India has emerged as a global hub for RPA services, with several RPA companies in India leading the charge in enabling smart, scalable, and sustainable factory operations. According to NASSCOM, India’s RPA market is expected to grow at a CAGR of 25% through 2027, driven by manufacturing, logistics, and financial services sectors.

This blog explores how RPA companies in India are empowering the next generation of smart factories, supported by data and real-world examples.

The Shift to Manufacturing 5.0: A Human-Centric Approach

Manufacturing 5.0 introduces a human-first, tech-enabled paradigm where automation supports workers rather than replacing them. The goals are to:

- Enhance productivity

- Enable real-time decision-making

- Personalize production

- Reduce operational errors

In this context, RPA automation plays a crucial role in bridging the gap between human intelligence and machine efficiency.

Why RPA is Vital for Smart Factories

RPA solutions automate repetitive, rules-based tasks across manufacturing functions like:

- Inventory and supply chain management

- Quality assurance reporting

- Invoice processing

- Equipment maintenance scheduling

- Compliance and audit trails

According to Deloitte’s Global RPA Survey:

- 78% of companies using RPA in manufacturing saw improved operational efficiency

- 59% reported cost savings over 20% within the first year of deployment

- 92% of companies plan to scale RPA across multiple departments

These automations result in:

- 30-60% cost reduction in manual processes

- 50% faster processing times

- Real-time analytics and performance tracking

How RPA Companies in India Are Driving Smart Manufacturing

India’s RPA ecosystem has evolved into a powerhouse of innovation. Leading RPA companies in India offer:

- Domain-specific RPA solutions for manufacturing

- Pre-built bots for ERP systems like SAP, Oracle, and Microsoft Dynamics

- Seamless integration with IoT platforms and MES (Manufacturing Execution Systems)

Top RPA implementation companies in India are helping manufacturers with:

- Digital twin integration: Using RPA bots to mirror physical operations for predictive insights

- Automated quality checks: Integrating RPA with vision systems for defect detection

- Predictive maintenance: Automating alerts and logs from sensor data

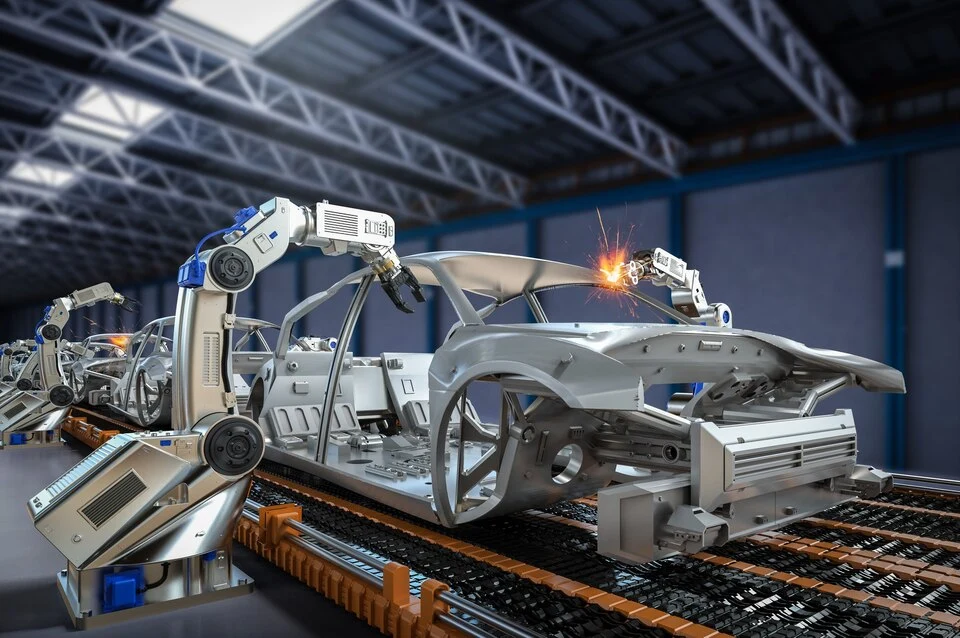

Case Study: RPA Automation in Indian Auto Manufacturing

A leading Indian automobile manufacturer partnered with an RPA services firm to automate:

- Procurement workflows

- Production reporting

- Vendor invoice reconciliation

Impact:

- Reduced reporting time by 80%

- Decreased invoice discrepancies by 65%

- Improved vendor onboarding time by 40%

Industry Insights: What Leading RPA Companies in India Are Saying

To understand how Manufacturing 5.0 is evolving, we gathered insights from leaders at key RPA companies in India:

- gNxt Systems

“Manufacturers are no longer looking for simple task automation — they want smart ecosystems. At gNxt, we’re focused on building AI-powered RPA agents that align with MES, ERP, and SCM platforms to deliver intelligent decision-making in real time.” — CTO, gNxt Systems - AutomationEdge

“Hyperautomation is the future of Indian manufacturing. Our clients demand end-to-end process visibility, which we enable by blending RPA with AI/ML.” - UiPath India

“The next phase of growth in India is RPA at scale — combining robots with human intelligence to build factories that are agile, responsive, and sustainable.” - Datamatics

“Manufacturing clients are increasingly opting for automation-first strategies. RPA not only improves efficiency but ensures compliance and reduces audit risks.”

These perspectives underline how Indian RPA providers are pushing the boundaries of innovation in smart manufacturing.

Choosing the Right RPA Partner in India

Not all RPA providers are created equal. When selecting from the top RPA companies in India, look for:

- Experience with manufacturing-specific RPA solutions

- Ability to integrate with your existing tech stack

- Scalable bot infrastructure

- End-to-end support from assessment to deployment

Some reputed RPA implementation companies in India also offer proof-of-concept (POC) projects to demonstrate ROI before full-scale deployment.

The Road Ahead: Hyperautomation and Beyond

With hyperautomation and AI-enhanced RPA gaining ground, Indian manufacturers can now:

- Use NLP (Natural Language Processing) to analyze supplier emails

- Apply ML (Machine Learning) for demand forecasting

- Enable self-healing bots that resolve errors without human input

As global supply chains demand resilience and agility, RPA companies in India are well-positioned to drive smart, sustainable transformation in manufacturing.

Final Thoughts

Manufacturing 5.0 is not a distant vision—it’s already unfolding across smart factories enabled by RPA automation. With the support of innovative RPA implementation companies in India, businesses can achieve higher productivity, smarter operations, and a more empowered workforce.

Whether you’re planning to kickstart your automation journey or scale existing systems, partnering with the right RPA services provider in India could be the key to future-ready manufacturing.

Read these blogs by gNxt Systems. They might interest you:

From Cost-Saving to Innovation: RPA Companies in India Are Driving Global Value

About Author

gNxt Systems is an IT professional services and product development company that follows Agile and Rapid development methodologies.